Making of the snare wires for Dyna-sonic

part 2

Making of the snare wires for Dyna-sonic

part 2

I know the "Puresound"

is making the wonderful wires for Dynasonic.

I know the "Puresound"

is making the wonderful wires for Dynasonic.

But, it's expensive for me...

So, I tried to make it by myself.

Yes, this is my original

idea!

I used these materials this time.

The left of pic is a investing material.

I used these materials this time.

The left of pic is a investing material.

The right is an aluminum sheet of 3mm thickness.

And, I used a Pearl "S-022" snare wires.

This has just suitable shape to process the following.

Others, a file and drill for the metal, and a soldering

iron are necessary.

Put investing material in a cup.

Put investing material in a cup.

Dissolve it with the water.

Dissolve it with the water.

Pour it to the snare wires that

was put on aluminum board.

Pour it to the snare wires that

was put on aluminum board.

This keeps the position of the wires

precisely.

It hardens in about 30 minutes.

When investment material is put into the water,

It hardens in about 30 minutes.

When investment material is put into the water,

it is parsed separately, and it can be eliminated.

Melt the solder with a soldering iron.

With the soldering iron of 100W/100V, keep for several

minutes....

Melt the solder with a soldering iron.

With the soldering iron of 100W/100V, keep for several

minutes....

The end plate comes off when enough heat is given to

it.

Remove remaining solder on the plate.

The end plate comes off when enough heat is given to

it.

Remove remaining solder on the plate.

This plate is turned over and soldered again!

This plate is turned over and soldered again!

Clean a solder side.

Clean a solder side.

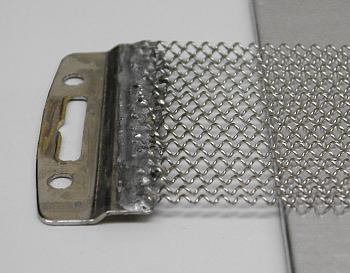

After soldering

Engrave the hole in the center of the plate.

After soldering

Engrave the hole in the center of the plate.

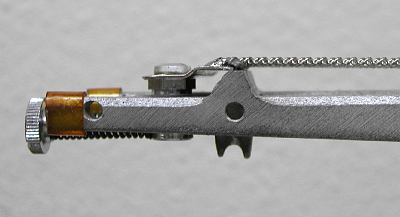

Side view

Yes, I was hoping for this form!!

An aluminum sheet resists heat and water...

Side view

Yes, I was hoping for this form!!

An aluminum sheet resists heat and water...

So, I selected an aluminum sheet of 3mm thickness.

(It has just 3mm from the top of the desk to the wires.)

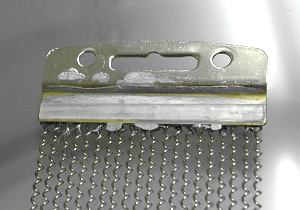

Back side

Back side

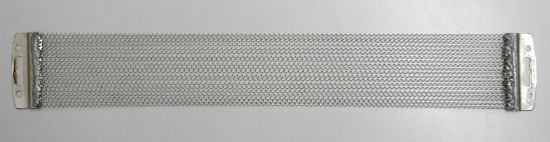

It's finished.

It's finished.

It is mounted in snare frame.

Let's file the burrs not to make a hole in your snareside

head!

It is mounted in snare frame.

Let's file the burrs not to make a hole in your snareside

head!

A height control screw is controled, and the wires

are made horizontal.

It is a pretty fine feeling!

A height control screw is controled, and the wires

are made horizontal.

It is a pretty fine feeling!

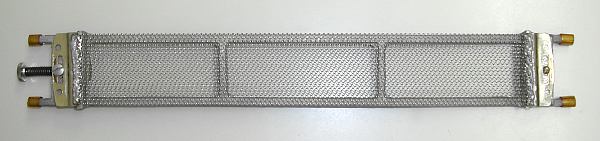

Whole view

Whole view

But, there is only one problem....

But, there is only one problem....

This is a new type of the snare frame.

This is a new type of the snare frame.

This frame doesn't have a height control screw.

It maybe needs some spacer between wires and frame...

So,,,

So,,,

I made the spacer from a CD case.

I made the spacer from a CD case.

Epoxied to the endplate

Epoxied to the endplate

I think that it's VERY GOOD!

I think that it's VERY GOOD!

Perfect ;-)

Perfect ;-)

Goodies &

info for ROGERS

Goodies &

info for ROGERS

Return to menu

Return to menu