Making of the snare wires for Dyna-sonic

Making of the snare wires for Dyna-sonic

I know the "Puresound"

is making the wonderful wires for Dynasonic.

I know the "Puresound"

is making the wonderful wires for Dynasonic.

But, it's expensive for me...

So, I tried to make it by my hands.

At that time, the following article

helped me very much.

The "Snare Wires for the

Rogers Dynasonic Snare Drum by John Scarpulla"

on the "Tech tips" page at www.rogersdrums.com

I appreciate Mr. John Scarpulla

so much!

The materials

Snare wires (I used Pearl S-022, because it isn't expensive.),

The materials

Snare wires (I used Pearl S-022, because it isn't expensive.),

Washers (1mm thickness), and Copper sheets (1mm & 1.5mm thickness)

You will be able to get all of them except for snare

wires at TOKYU HANDS.

TOKYU HANDS is a famous general store in Japan.

Hacksaw

Hacksaw

Soldering iron

Soldering iron

(100W at AC 100V in Japan)

Others, a file and drill for the metal, some clamps,

and wood chips are necessary.

A copper sheet is being cut.

Two plates are respectively necessary.

A copper sheet is being cut.

Two plates are respectively necessary.

The dimensions are 1.5mm x 7mm x 50mm & 1mm x 21.5mm x 50mm.

But, this digit will change with the wires which you

use.

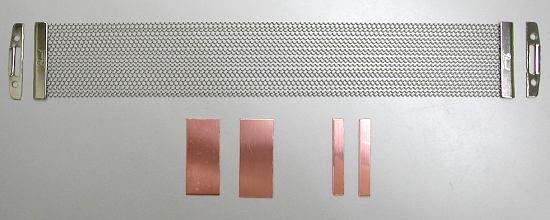

The parts before assembling

Cut off the ears at either side of the S-022.

The parts before assembling

Cut off the ears at either side of the S-022.

The pic which expected completion

The pic which expected completion

This is Japanese disposable chopsticks called "WARI-BASHI".

This is Japanese disposable chopsticks called "WARI-BASHI".

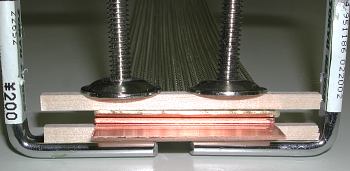

Clamps and cut chopsticks

Clamps and cut chopsticks

Before soldering

Before soldering

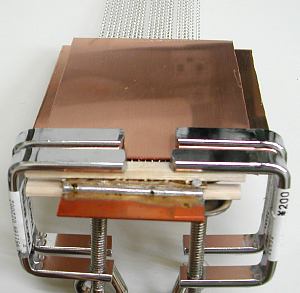

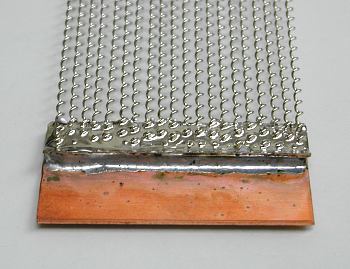

After soldering

Many clamps are used to keep the position of the wires.

After soldering

Many clamps are used to keep the position of the wires.

Snareside

Snareside

Back side

A discoloration of the copper plate will be cleaned

by a cymbal cleaner.

Back side

A discoloration of the copper plate will be cleaned

by a cymbal cleaner.

Drill a diameter 5mm hole in the center of the plate.

The space of the hole and the hole is nearly 328mm.

And let's file the burrs not to make a hole in your

snareside head!

The upper is the Puresound "PD-14".

The Puresound has 16 strands, but the modified S-022

has 20 strands.

The upper is the Puresound "PD-14".

The Puresound has 16 strands, but the modified S-022

has 20 strands.

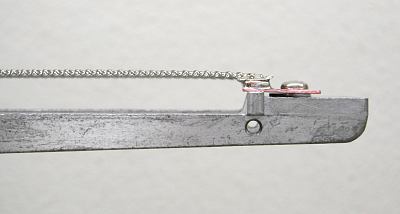

Assembling with the snare frame

Assembling with the snare frame

Tension adjustment screw's side

The washer of 1mm thickness is put as a spacer.

Tension adjustment screw's side

The washer of 1mm thickness is put as a spacer.

Butt side

The washer is used in the same way.

Butt side

The washer is used in the same way.

It's finished...

It's finished...

Thank you very much Mr. John Scarpulla

again!

Thank you very much Mr. John Scarpulla

again!

Goodies &

info for ROGERS

Goodies &

info for ROGERS

Return to menu

Return to menu